Eaton Fuller 9-, 10-, 13-, 18-speed Transmission: FRO-, FRLO-, FS-, AT-, CL-, RT-, RTLO-, RTO-, RTX-, T-Series Service Manuals, Wiring Diagrams in PDF free download

See also: Eaton Fuller/ Autoshift/ Smartshift/ Autoselect Transmission Fault Codes List & PDF

| Title | File Size | Download Links |

| Eaton 2A-92 Auxiliary Transmission Service Manual [PDF] | 20.8Mb | Download |

| Eaton 4106 and 5206 Transmission Service Manual [PDF] | 5.1Mb | Download |

| Eaton 6609 series Transmission Service Manual [PDF] | 57.7Mb | Download |

| Eaton AT-1202 Transmission Service Manual [PDF] | 2.2Mb | Download |

| Eaton CL-450 Transmission Service Manual [PDF] | 2.6Mb | Download |

| Eaton CL-550 Transmission Service Manual [PDF] | 2Mb | Download |

| Eaton Clark 280V Transmission Service Manual [PDF] | 1.6Mb | Download |

| Eaton Clark 280VHD Transmission Service Manual [PDF] | 1.7Mb | Download |

| Eaton Engine Configuration Settings – Automated Transmissions (PDF, 2MB) [PDF] | 412.8kb | Download |

| Eaton F-5405B-DM3 Transmission Service Manual [PDF] | 26.5Mb | Download |

| Eaton FO-6406A-ASW Transmission Service Manual [PDF] | 12.8Mb | Download |

| Eaton FR-14210B Transmission Service Manual [PDF] | 15.6Mb | Download |

| Eaton FRLO-14410C Transmission Service Manual [PDF] | 1.9Mb | Download |

| Eaton FRLO-16410C-T2 Transmission Service Manual [PDF] | 41.2Mb | Download |

| Eaton FRO-16210C Transmission Service Manual [PDF] | 9.9Mb | Download |

| Eaton FS-4205B Transmission Service Manual [PDF] | 3.1Mb | Download |

| Eaton FS-5106A FS6206A Transmission Service Manual [PDF] | 1.7Mb | Download |

| Eaton FS-5205A Transmission Service Manual [PDF] | 7.5Mb | Download |

| Eaton FS-6105 Transmission Service Manual [PDF] | 2.8Mb | Download |

| Eaton FS-6106 Transmission Service Manual [PDF] | 2.1Mb | Download |

| Eaton FS-6106A Transmission Service Manual [PDF] | 25Mb | Download |

| Eaton FS-7206A Transmission Service Manual [PDF] | 14.3Mb | Download |

| Eaton FS-8206A Transmission Service Manual [PDF] | 13.7Mb | Download |

| Eaton FSO-6109A Transmission Service Manual [PDF] | 28.7Mb | Download |

| Eaton Fuller 10 Speed Transmission Service Manual [PDF] | 8Mb | Download |

| Eaton Fuller 13 Speed Road Ranger Service Manual [PDF] | 4.1Mb | Download |

| Eaton Fuller 18 Speed Transmission Service Manual [PDF] | 2.7Mb | Download |

| Eaton Fuller 9 Speed Transmission Service Manual [PDF] | 69.9Mb | Download |

| Eaton Roadranger Service Manual [PDF] | 1.1Mb | Download |

| Eaton RT-6610 Series Transmission Service Manual [PDF] | 19.4Mb | Download |

| Eaton RT-7608LL Transmission Service Manual [PDF] | 23.9Mb | Download |

| Eaton RT-8609 Transmission Service Manual [PDF] | 23Mb | Download |

| Eaton RT-906 Transmission Service Manual [PDF] | 7.5Mb | Download |

| Eaton RTF-11608 Transmission Service Manual [PDF] | 25.7Mb | Download |

| Eaton RTLC-16609E Transmission Service Manual [PDF] | 15.9Mb | Download |

| Eaton RTLO-10 speed Transmission Service Manual [PDF] | 9.2Mb | Download |

| Eaton RTLO-11118A-MT and RTLO-9118A MT Transmission Service Manual [PDF] | 952.9kb | Download |

| Eaton RTLO-11118A-MT Transmission Service Manual [PDF] | 3.8Mb | Download |

| Eaton RTLO-14613B and RTLOF-14613B Transmission Service Manual [PDF] | 3.4Mb | Download |

| Eaton RTLO-16618A Transmission Service Manual [PDF] | 3.7Mb | Download |

| Eaton RTLO-16713A Transmission Service Manual [PDF] | 32.5Mb | Download |

| Eaton RTLO-18718B Transmission Service Manual [PDF] | 17.5Mb | Download |

| Eaton RTLO-18913A Transmission Service Manual [PDF] | 17.5Mb | Download |

| Eaton RTLO-18913A-T2 Transmission Service Manual [PDF] | 17.5Mb | Download |

| Eaton RTLO-18918A-AS3 Transmission Service Manual [PDF] | 18Mb | Download |

| Eaton RTLO-18918B Transmission Service Manual [PDF] | 17.5Mb | Download |

| Eaton RTLO-18918B-AS Transmission Service Manual [PDF] | 4.4Mb | Download |

| Eaton RTLO-20913A Transmission Service Manual [PDF] | 2.8Mb | Download |

| Eaton RTLOF-18610B Transmission Service Manual [PDF] | 10.2Mb | Download |

| Eaton RTO-11607L Transmission Service Manual [PDF] | 4.4Mb | Download |

| Eaton RTO-13109B-AT Transmission Service Manual [PDF] | 3.3Mb | Download |

| Eaton RTO-13707MLL Transmission Service Manual [PDF] | 20.7Mb | Download |

| Eaton RTO-15618 Transmission Service Manual [PDF] | 3.7Mb | Download |

| Eaton RTO-16910B-AS2 Transmission Service Manual [PDF] | 8.3Mb | Download |

| Eaton RTO-6613 Transmission Service Manual [PDF] | 3Mb | Download |

| Eaton RTO-9109B-AT Transmission Service Manual [PDF] | 5Mb | Download |

| Eaton RTO-958LL Transmission Service Manual [PDF] | 59.7Mb | Download |

| Eaton RTOF-11607L Transmission Service Manual [PDF] | 4.4Mb | Download |

| Eaton RTOF-11610 Transmission Service Manual [PDF] | 3.8Mb | Download |

| Eaton RTX-11509 Transmission Service Manual [PDF] | 3.6Mb | Download |

| Eaton RTX-12510 Transmission Service Manual [PDF] | 3.5Mb | Download |

| Eaton RTX-13609B Transmission Service Manual [PDF] | 6.4Mb | Download |

| Eaton RTX-16710C Transmission Service Manual [PDF] | 13.7Mb | Download |

| Eaton T-11605 Transmission Service Manual [PDF] | 2.4Mb | Download |

| Eaton T-11607A Transmission Service Manual [PDF] | 3.2Mb | Download |

| Eaton T-905 Transmission Service Manual [PDF] | 1.9Mb | Download |

| Eaton T-955 Transmission Service Manual [PDF] | 39.2Mb | Download |

| Eaton Transmission Guide [PDF] | 5.8Mb | Download |

| Eaton TRSM0050 RU-RU Service Manual [PDF] | 6.4Mb | Download |

| Unit Exchange Program Guide (PDF, 1MB) [PDF] | 281.3kb | Download |

Eaton Fuller Transmissions

EATON Corporation is a Fortune 500 company that manufactures and distributes truck gearboxes, electrical distribution and controls, engine components, hydraulic systems, and semiconductor equipment worldwide from its headquarters in Cleveland, Ohio, USA. The company has factories in 28 locations across six continents and exports its goods to 115 nations. In 1946, EATON started doing business in Europe after purchasing a tiny percentage of a firm that made engine pumps and gears. Plants producing EATON products may now be found in France, Germany, Italy, Monaco, the Netherlands, Poland, Spain, and the United Kingdom.

Big names in the truck industry trust EATON to provide their gearboxes, clutch mechanisms, drive axles, and braking systems for models with GVWRs between 8.0 and 44.0 tons. The company’s ability to adapt quickly to market demands and provide flawless designs is supported by a strong European technical center and a global network of marketing centers in various nations. In 1958, the company’s experts elevated the EATON name for the first time by providing a breakthrough Fuller gearbox with two intermediate shafts. Over four million have been manufactured since then. In 1985, an extra 3-speed gearbox and two intermediate shafts were added to the lineup in the form of the Twin Splitter. In 1986, a semi-automatic variant of the SAMT was introduced, making it the first European design to be optimized for demanding industrial use. The EATON SAMT line of motor controls had an improvement in 1996.

The constant mesh gears of the 6- and 9-speed manual gearboxes now make up the bulk of the company’s manufacturing schedule. The 94th generation included a new 16-speed gearbox to this series, differentiating itself with synchronizers that allow for easier gear changes. This was reflected in the switching speed, which, together with a light box and quieter operation, propelled the assembly’s design into the top tier in Europe.

Let’s take a closer look at the engineering that goes into EATON transmission. At the outset, think about the benefits brought to the node by a circuit with two intermediates, also called transfer shafts.

Because the torque is shared across two sets of gears, you may lower the breadth of all the teeth by around 40% without increasing the tension on them. As a result of the main shaft and its associated gears being able to freely “float” between the two sets of intermediate shaft gears, dynamic loads are kept to a minimum. So, the total length of the knot may be shortened without compromising its strength or durability.

Spur gears are used for everything. Because of the teeth’s design and some further adjustment, the transmission is subject to few stresses and less noise. Having more than two teeth engaged at once helps reduce noise by 5 to 7 dB, and the larger contact zone of the teeth makes this possible. Using this method, load is distributed more evenly, and tensions on the teeth’s surface are decreased. Bearings experience less stress as a result. As an added bonus, the main shaft gears don’t have to use bearings, bushings, or broad hubs to compensate for the bending moments that occur with helical gears, shortening the overall length of the box.

When compared to the situation when just one intermediate shaft is present, the forces operating on the bearings of each intermediate shaft are much reduced. This is because there is no axial load in the engagement, and the transmitted torque is reduced by half.

Eaton Fuller 13 Speed Transmission

Short sliding clutches are used to change gears. All of the teeth are the same length along the engagement line, making them easy to use and dependable.

All parts of the gearbox, not only the bearings and teeth, benefit from these additions to lengthen their useful lives.

Twenty years of usage in heavy vehicles in harsh environments have shown that Fuller transmissions are durable and dependable. The firm was able to provide a broad selection of modularly constructed models to its clientele as a result. A 5-speed forward gearset from the main gearbox may be combined with a two or three-speed secondary unit positioned in the trunk to create a wide variety of configurations.

Over 40 transmission modules ranging from 5 to 15 forward gears were scheduled for manufacturing in 1999. EATON’s transmissions may be configured in a wide variety of ways, allowing the company to provide solutions for almost every transportation need. The modular design has another key advantage: the characteristics of the transmission may be readily modified by changing the auxiliary section positioned on the rear of the box. The same idea enables you to have a limited number of replacement parts on hand, which considerably simplifies maintenance and repair across the board for the full model range.

Fuller transmissions are made in all of the company’s plants utilizing the same production procedures and rigorous standards in terms of both product quality and materials. This helps the organization to adapt swiftly to changing market circumstances and to have interchangeable components and their groups accessible globally.

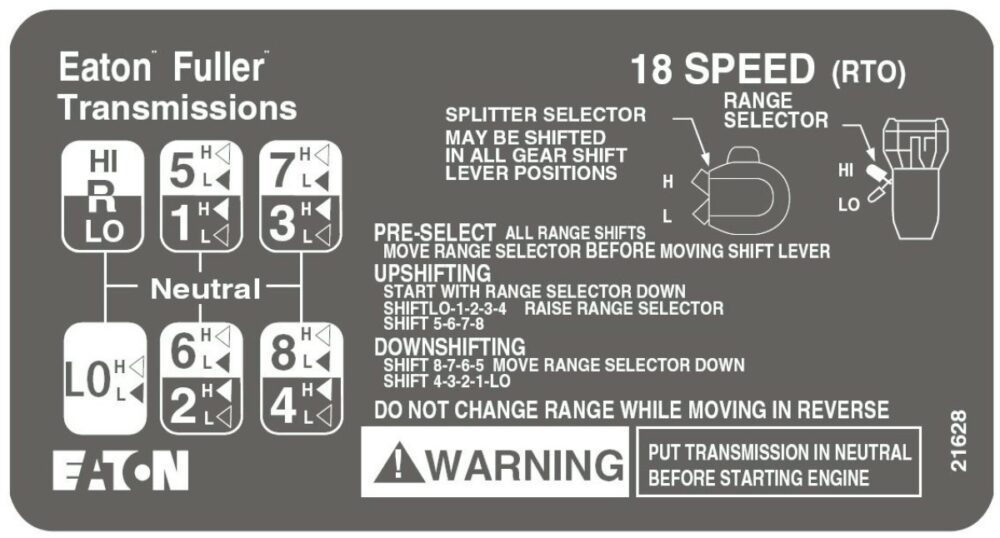

Eaton Fuller 18 Speed Transmission Diagram

Eaton Fuller 18 Speed Transmission Diagram

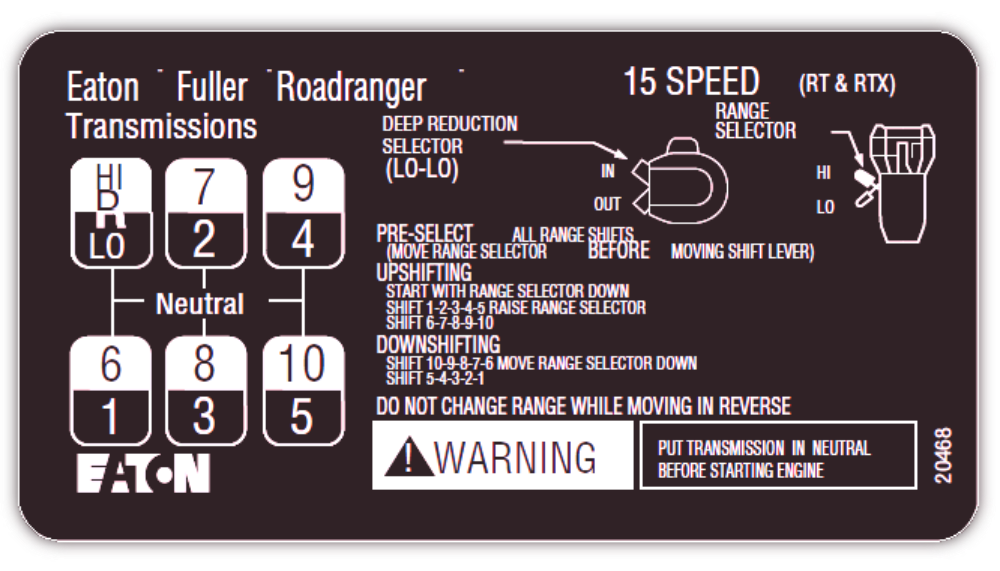

Eaton Fuller Transmission 15 Speed Shift Pattern

Eaton Fuller transmission 15 speed shift pattern

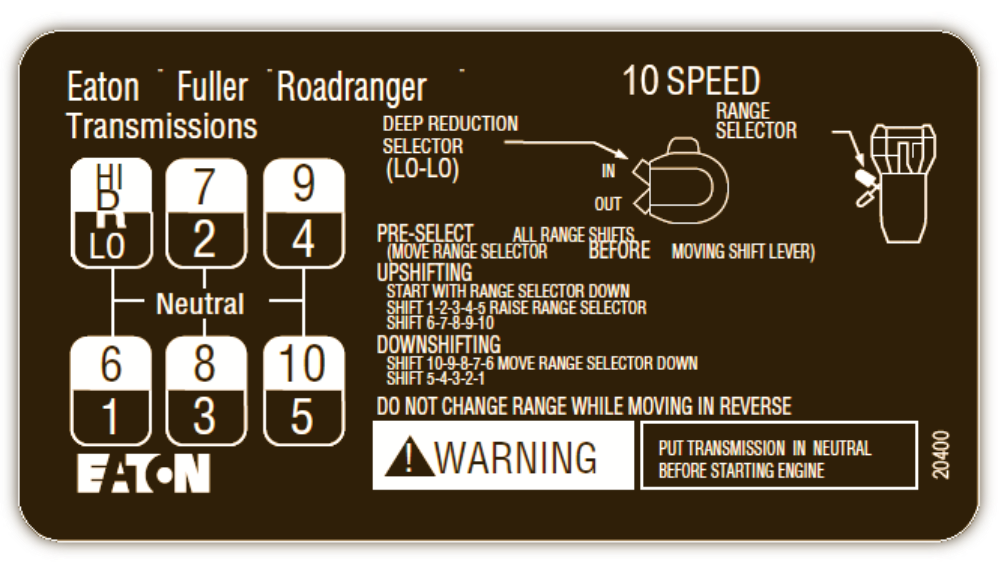

Eaton Fuller transmission 10 speed shift pattern

Eaton Fuller transmission 10 speed shift pattern