Paccar Engines: owner’s, service and maintenance manuals, error codes list, DTC, spare parts manuals & catalogues, wiring diagrams, schematics free download PDF

| Title | File Size | Download Links |

| Paccar 2005-2010 Multiplexed Electrical System Service Manual [PDF] | 5.7Mb | Download |

| Paccar 2005-2010 Service Manual [PDF] | 5.7Mb | Download |

| Paccar 2010 Multiplexed Electrical System Service Manual [PDF] | 6.9Mb | Download |

| PACCAR MX 13 engines DE 527061 [PDF] | 4.4Mb | Download |

| PACCAR MX 13 engines RU 527061 [PDF] | 4.4Mb | Download |

| Paccar MX ECM Circuit Diagram [PDF] | 320.9kb | Download |

| Paccar MX-11 Operator’s Manual [PDF] | 6.5Mb | Download |

| Paccar MX-11 / MX-13 Programming Manual [PDF] | 2.7Mb | Download |

| Paccar MX-13 2013 Diagnostic Service Manual [PDF] | 8.3Mb | Download |

| PACCAR MX-13 Engines [PDF] | 4.2Mb | Download |

| Paccar MX-13 EPA13 Overhaul Service Manual [PDF] | 10.5Mb | Download |

| Paccar MX-13 Operator’s Manual [PDF] | 4.7Mb | Download |

| Paccar MX11-MX13 Engines 2019 Brochure [PDF] | 12.9Mb | Download |

| Paccar parts catalog 2022 [PDF] | 4.8Mb | Download |

| Paccar PX 8 Operator’s Manual [PDF] | 2Mb | Download |

| Paccar PX-7 Engine Operator’s Manual [PDF] | 3.1Mb | Download |

| Paccar PX-9 Operator’s Manual [PDF] | 2.7Mb | Download |

Paccar engine Manuals PDF

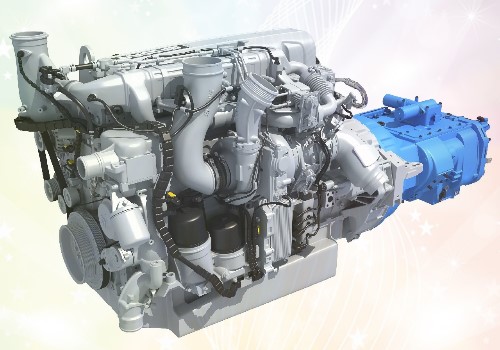

American truck manufacturer Paccar is among the world’s top three. It also manufactures engines for use in DAF vehicles and other brands.

Motors having a displacement of 12.9 liters (generating 360–510 hp) fall under the MX classification. Torque ratings range from 1775 Nm to 2500 Nm, and they stand out for their dependability. Power units on the series have SMART injection and SCR technology, making them compatible with the Euro-5 environmental classification. In addition, the MX engine can meet EEV standards because of the existence of a particle filter.

The reliability of Paccar MX engines has increased due to their redesign. In addition, the designers successfully extended the maintenance interval to 90,000 kilometers.

If synthetic oil and a centrifugal filter element are used, the distance between maintenance stops climbs to 150,000 km.

One of the motor’s characteristics is a built-in motor brake, which can be used to gradually increase the engine’s output. From 1500 rpm, it can provide 200 kW of braking power, and at 2100 rpm, it can generate 325 kW.

Let’s quickly compare the characteristics of each candidate:

Whether you choose to call it “MX 265” or “360 horses,” that’s how much power you get from this beast of a generator. In order to reach the aforementioned specifications, a speed range of 1500–1900 rpm is required. At 1000-14,000 rpm, the torque is 1775 N * m. Compatible with DAF CF85 vehicles.

MX 300. The power output of 300 kW (410 hp; @ 1500–1900 rpm) with such an engine. Two thousand newton meters is equivalent to four thousand hundred revolutions per minute. Incorporating CF85 and XF105 upgrades.

The MX 340 has a 460-horsepower engine that can turn at speeds between 1500 and 1900 rpm, making it capable of producing 340 kW of power. Produces 2300 Nm of torque between 1000 and 1400 rpm. Equipped on the CF-85 and XF-105.

MX 375. 510 horsepower (or 375 kW) of power may be generated by the engine. The range of 1500–1900 rpm is optimal for achieving the necessary qualities. At a speed of 1000-1400 rpm, the torque is 2500 Nm. The CF 85 and XF 105 had the power plant mounted atop the aircraft.

Paccar’s more widely used MX 11 and MX 13 engines deserve their own group because they are found in so many different types of vehicles. Below, we shall go deeper into their technical aspects and design nuance.

MX-13

Featuring a cutting-edge injection system and a variable geometry turbocharger, the Paccar MX-13 is a 12.9-liter Euro 6 engine. As an added bonus, the developers have included a new and better control system that ensures productivity without increasing expenses.

The Paccar engine is a cutting-edge innovation that satisfies present-day standards for reliability and environmental friendliness. Their durability, enhanced performance, and low fuel costs make them an excellent choice. They serve as the primary motive force for DAF trucks and other vehicles.

The manufacturer includes a recirculation system, particulate filter, and selective catalytic reduction (SCR) to ensure the lowest possible environmental impact. Extra torque at low RPM in top gear from the motors is a boon to fuel economy.

The MX-13 motor family features:

- There are 315 kilowatts (kW) or 428 horsepower (1600 rpm) available from this engine. This motor generates 355 kW, or 483 hp, at 1600 rpm and a torque of 2150 or 2300 N * m between 900 and 1365 rpm and between 900 and 1125 rpm.

- The engine produces maximum power at 1675 rpm when it produces 390 kW (530 hp), and the torque is 2350 or 2500 N * m (900 or 136 lb-ft, respectively).

- Two different speeds (1000-1425 and 1000-1460 rpm) produce torque values of 2500 and 2600 N * m, respectively.

The diesel turbocharged supercharged total combustion internal combustion engine is under consideration. SCR, EGR, and DPF systems are all available. The Euro-6 requirements have been met in full. The compression ratio is 18.5 to 1, the cylinder diameter is 13, and the piston stroke is 16.2 cm.

Components of the layout:

- A steel crankshaft with no counterweights and a cast iron cylinder block.

- Each cylinder has four valves.

- The drive is mounted in the back.

The fuel and air delivery system of the Pakkar MX-13 engine has been upgraded. The fuel is heated and prepared by a heater installed within the tank. The water is automatically drained and filtered. Nozzles capable of delivering an ignitable mixture at pressures up to 2500 bar are fitted at the output.

Paccar MX-13

A turbocharger and an air cooler are part of the system that draws in air. The turbocharger’s geometry can be adjusted as needed. A block houses the various components of the lubrication system: filters, an oil cooler, pipes, valves, and a thermostat.

A centrifugal bypass valve is included for long-term reliability. The oil-cleaning filter element is a full-flow type, and the cooler is managed by a thermostat in a stainless-steel heat exchanger.

MX-11

This vehicle is powered by a PaccarMX-11-10.8-liter engine, which may generate 290–440 horsepower, differences in size, profitability, weight, and noise level. DAF Trucks of the Netherlands developed and began manufacturing this model in the fall of 2013.

Peculiarities:

- Improved rigidity characteristics and integrated systems for the cylinder block of the 6-cylinder variant;

- Top-mounted double camshaft in the cylinder head; variable-geometry turbocharger; high-pressure fuel delivery system; cutting-edge engineering for optimal performance.

The developers have included an improved double camshaft. Manufacturers employed advanced construction techniques that included adding graphite and a vertical rib to boost rigidity and quietness. The cylinder block has been outfitted with as many features as possible to extend its useful life. Pipelines, for instance, can take the form of channels, and pressure-generating pumps can be embedded directly into the concrete itself.

The fuel delivery system utilizes a pre- and post-injection device and a common frame that provides a pressure of 2500 bar. This layout makes it possible to cut back on fuel use and ensures that it gets distributed evenly.

Several improvements have been made to the engine as well, such as the elimination of the need for a separate drive for the fan by mounting it directly to the crankshaft. This results in lower operating and fuel expenses. The motor features a water pump, a combined generator/compressor unit, and an oil block with a filter integrated into its design.

Paccar FR

Paccar FR engines are a subset of this larger category; they are 4-cylinder power units that are vertically arranged; they are turbocharged, and they use clean combustion to power the vehicle. To be seen as a row of the following prototypes:

- engine producing 118-160 hp at its peak RPM of 1900, with the torque of 550 Nm; engine producing 103-140 hp at its peak RPM of 1900, with the torque of 550 Nm;

- 136 – 185 hp engine at 200 rpm with 700 Nm of torque; 152-207 hp unit with peak power at 2100-2300 rpm and 760 Nm of torque.

The FR has a working volume of 4.5 liters, a cylinder diameter of 10.7 cm, and a piston stroke of 12.4 cm. The motor has the following features: Features a cast-iron ladder-type frame, a cylinder head with separate channels for starting and releasing the engine, aluminum pistons with symmetrical concave chambers and a cooling channel, a forged camshaft with induction hardening, a common-rail fuel injection system, an adjustable starter, and electronic control.

Standards and technologies for SCR and EEV Paccar engines ensure that they operate at peak efficiency. The most important ones are as follows:

- The EEV is a benchmark for a low-emission vehicle. SRC technology and smart injection are used to regulate the combustion process. Many models of DAF trucks use the FR, PR, and MX variations of this class of motor.

- SCR refers to a method of selective catalytic breakdown. Its purpose is to purify exhaust fumes to conform to Euro 5 and EEV standards. Particulate filters and enhanced fuel delivery support the system’s fundamental feature—the afterburning of spent exhaust gases.