Detroit Diesel DD15 operators, service and maintenance manuals, error codes list, DTC, spare parts manuals & catalogues, wiring diagrams, schematics free download PDF

See also:

| Title | File Size | Download Links |

| Detroit DD15 Valve Adjustment [PDF] | 40.3kb | Download |

| Detroit Diesel DD 13 / 15 Fuel System [PDF] | 735.7kb | Download |

| Detroit Diesel DD13-DD15 Application / Installation Manual [PDF] | 10.7Mb | Download |

| Detroit Diesel DD15 – EPA07 and EPA10 DD Platform, EGR Delta Pressure Sensor Update [PDF] | 366.3kb | Download |

| Detroit Diesel DD15 Engine Workshop Manual [PDF] | 11.6Mb | Download |

| Detroit Diesel Dd15 Manual Del Usuario [PDF] | 16.8Mb | Download |

| Detroit Diesel service manual dd15 [PDF] | 1.8Mb | Download |

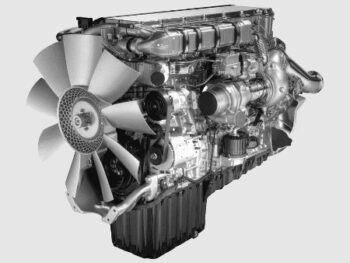

Detroit Diesel DD15

Detroit Diesel Corp (DDC), one of the leading American engine producers, revealed its newest Detroit Diesel DD15 engine, made for heavy vehicles, in the center after five years of design and development work and spending of roughly $1.5 billion.

Detroit Diesel DD15 is a 14.8-liter, 6-cylinder engine that can produce 455 to 560 horsepower, depending on the configuration. This engine may meet the EPA-07 environmental requirement for the United States with its integrated EGR system, and the EPA-10 regulations can be met by fitting the engine with an ADBLE (SCR) barrel. After the DD15 goes into production for real, a 12.8-liter DD13 model and a 15.6-liter DD16 engine with 630 horsepower will follow.

Furthermore, American Motors claims that by adding two turbines to the motor, they were able to increase the overall output by 50 horsepower. Assuming that the first turbine is installed in a conventional manner to boost the pressure provided to the air cylinders, the second turbine is positioned immediately on the exhaust tract to improve power by spinning from the exhaust gas flow. To put it another way, these gases would have been wasted if they had been released previously, but they will now help the DD15 save gasoline.

Detroit Diesel DD15

The DD15 prototype went through rigorous testing under a wide range of conditions, some of which were extremely challenging, as part of the process of developing a new engine. Road testing in the US, Germany, and Japan was conducted on over 25 different prototypes to ensure their dependability. Over the course of testing, these motors operated over 100,000 times each, which is the equivalent of driving several million kilometers.

“In the past, truck drivers faced tough trade-offs between performance and fuel economy, vehicle handling and durability, lengthy service intervals, and cheap but frequent servicing. Freightliner LLC Corporation President Chris Patterson has said that the company’s new DD15 engine has the potential to make all of these “or” statements true.

When compared to the Series 60 models that came before it, the DD15 has a 75% increase in torque, a 30% reduction in noise, and a 5% decrease in fuel consumption. Apparently, drivers will value being able to get peak torque at a relatively low engine speed (between 800 and 900 rpm) (in Series 60, this turned out only at 1100-1300 rpm).

This new DD15 engine dates back to April of 2008. Customers have received Cascadia tractors, which has led to orders for additional Freightliner models, including the flagship trucks of Western Star and Sterling. Furthermore, according to the automaker’s officials, the new motor platform will replace the four model ranges of engines that are now utilized in Daimler Trucks’ trucks. That is, it will be perfected in the Mercedes-Benz and Mitsubishi Fuso assembly factories in Mannheim, Germany, and Kawasaki, Japan, respectively.